Our History

B&W celebrates more than 150 years of industry firsts and achievements in innovation.

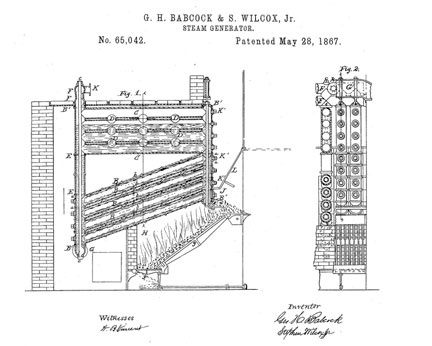

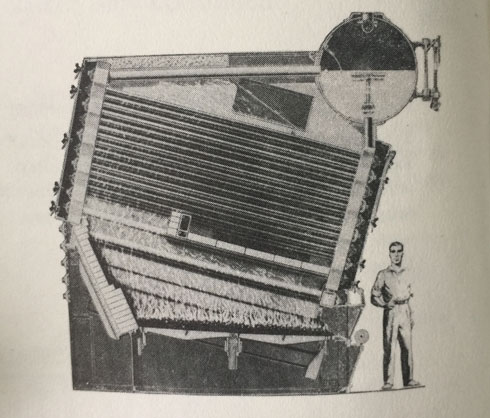

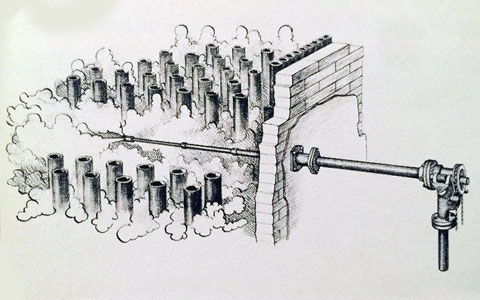

With a patent awarded in 1856 (S. Wilcox and O.M. Stillman), George Babcock and Stephen Wilcox joined forces to design and market a boiler that increased heating surfaces for better efficiency and was both effective and safe.

B&W is established in Providence, Rhode Island, when George H. Babcock, Stephen Wilcox, Jr., and Joseph P. Manton form Babcock, Wilcox and Company to manufacture and market a water-tube steam boiler. This invention patented by Babcock and Wilcox marks the beginning of and set the standard for safe, reliable steam-generated power.

B&W sells its first boiler to Carpenter & Cross of Providence for the Valley Worsted Mills.

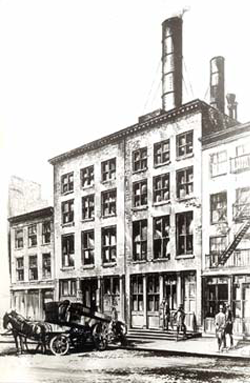

Babcock moves to New York City where he opens an office on Broadway.

As a salesman for Hope Iron Works, Wilcox also moves to New York City and leases an office at 44 Cortlandt Street, which would later become the company’s headquarters.

In the first year of the new decade, Joseph Manton withdrew from his partnership with Babcock and Wilcox. His departure, however, was only a minor setback, for the company continued to gain momentum. B&W earned national recognition at Philadelphia’s sensational Centennial Exhibition.

B&W headquarters is established in New York City.

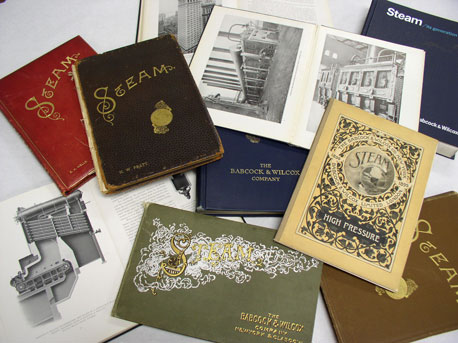

Babcock and Wilcox publish Requirements of a Perfect Steam Boiler, a simple, 12-point set of guidelines for the ideal boiler. With this document, B&W creates a reputation of excellence and an industry standard for boiler manufacture.

B&W publishes the first edition of Steam/its generation and use. To this day, Steam is the most comprehensive study of steam power available and is used as a textbook throughout the world.

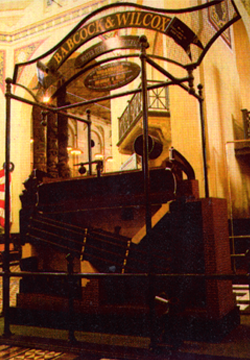

Babcock and Wilcox are awarded a gold medal for their full-size, 150 horsepower cast iron front boiler specially created for the international exhibition in Philadelphia to commemorate the Centennial of American Independence. Though the initial investment was expensive, the strategic decision to showcase their boiler at the Exposition is rewarded. The public is captivated by the possibilities of the boiler and new orders begin to roll in. B&W’s first major customers: sugar refineries.

The Centennial boiler showcased in 1876 is sold to DeCastro and Donner, a sugar refinery in Brooklyn, New York. It remains in service for 24 years.

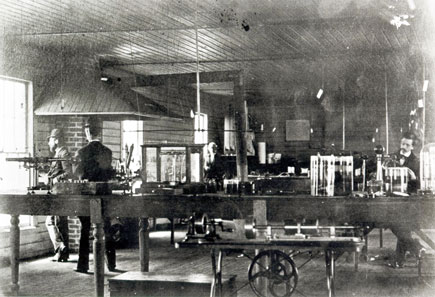

Thomas Edison orders a boiler to power his machine shop and laboratory in Menlo Park, New Jersey.

The 1880s saw the birth of the electrical age with the opening of Brush Electric Light Company in Philadelphia, and Thomas Edison’s Pearl Street station in New York City. Babcock & Wilcox equipment powered both, and the young company extended its focus to European and government applications.

Babcock is a founding member of the American Society of Mechanical Engineers, established in New York City.

Babcock becomes the first president of the newly incorporated New Jersey company, The Babcock & Wilcox Company.

Nathaniel Pratt, who would be B&W’s second president, opens the company’s first non-U.S. office in Glasgow, Scotland.

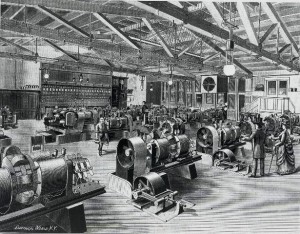

Philadelphia’s Brush Electric Light Company, illuminated by four 73-horsepower B&W boilers, is the first electricity-producing central generating station in America. Boilers are also sold to Edison Electric Light Company for the Holborn Viaduct Station in London and for the International Electric Exposition in Paris.

Thomas Edison’s Pearl Street station in New York City, operating with four B&W boilers, is the first public utility. Electric lighting becomes a reality.

The Babcock & Wilcox Company opens an office in London to pursue overseas business. From 1884 to 1887, branches are opened in Manchester, Sydney, Paris and Brussels.

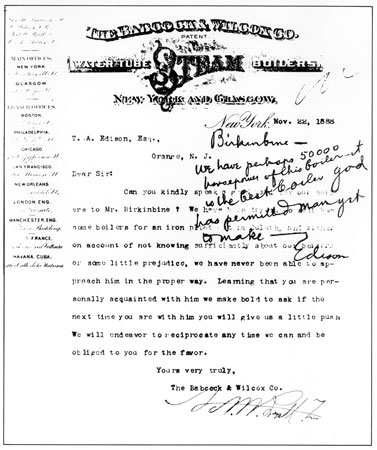

Thomas Edison, who had B&W boilers in his laboratory, writes that a B&W boiler is “the best boiler God has permitted man yet to make.”

The success of the new boiler built for Wilcox’s steam yacht Reverie convinces the U.S. Navy and British Admiralty to use B&W’s marine boilers.

To follow up the successful performance at the Philadelphia Centennial Exposition 13 years earlier, a B&W boiler captures the top prize at the Exposition Universelle in Paris, France.

Babcock & Wilcox, Limited is incorporated in Britain and effectively consolidates the company’s international business with headquarters in London.

Though George Babcock and Stephen Wilcox died 19 days apart in 1893, their legacy of designing and supplying the highest-quality equipment and providing superior customer service lives on today. The 1890s signaled B&W’s first firm foothold overseas and the establishment of its marine boiler service. The company closed out the nineteenth century with new leadership, a steadfast relationship with the utility industry and a developing relationship with the U.S. Navy.

B&W establishes a Marine Department. The U.S. Navy purchases its first coal-fired water-tube marine boiler from B&W. In the coming years, this boiler is ordered for the USS Marietta, Annapolis and Chicago. The British share the U.S. Navy’s enthusiasm for B&W marine boilers, which power many British ships and help establish B&W as the leader in marine boiler production.

B&W continues to pursue global expansion as licensees are founded in France and Germany (Deutsche Babcock AG) and a branch is established in Mexico. Edwin H. Wells, the fourth president of B&W, commences his 21-year presidency, which is characterized by tremendous growth and expansion.

Vølund A/S is founded, producing heating systems and steam laundries.

William D. Hoxie, who would succeed Wells as president, introduces a completely redesigned boiler for the Alert. This marine boiler’s combustion process is revolutionary and helps establish the water-tube boiler as the standard for marine service.

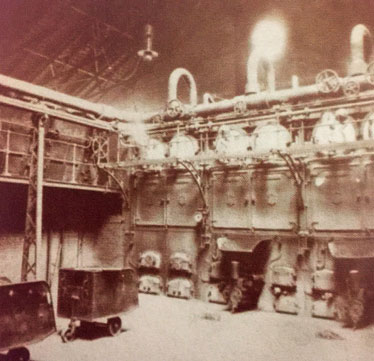

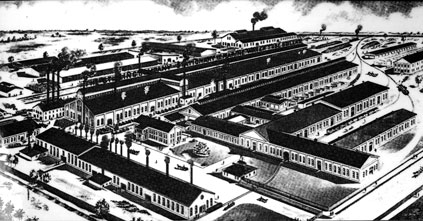

B&W’s first manufacturing facility opens in Bayonne, New Jersey. Special equipment is installed for the fabrication of forged steel headers, which house B&W’s unique staggered tube arrangement design.

New York City's first subway is powered by B&W boilers.

In Chicago, B&W provides boilers to Commonwealth Edison Company’s Fisk Street Station, the first public utility station completely powered with steam turbines.

Boiler cleaning business Diamond Power Specialty Company is established in Michigan.

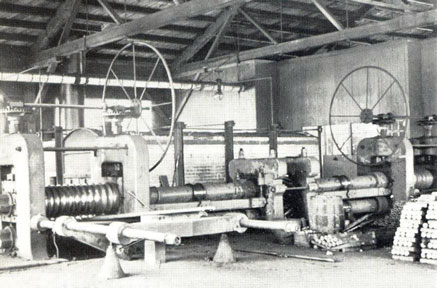

B&W acquires the Pittsburgh Seamless Tube Company in Beaver Falls, Pennsylvania, later renamed the Babcock & Wilcox Tube Company. This acquisition allows B&W to develop the stronger, more reliable, more economical “hot-finished” seamless steel tube.

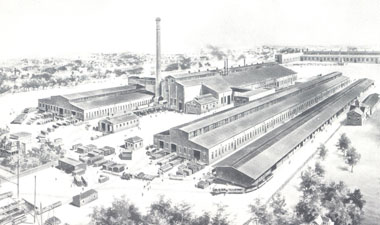

B&W purchases the Stirling Consolidated Boiler Company Plant’s 65-acre facility in Barberton, Ohio. With this acquisition, the company begins production of bent-tube boilers. Only 40 years since B&W was founded, Stirling boilers were now being fabricated at up to 823 horsepower and 300 pounds pressure, or 16 times more powerful than the 1867 water-tube boiler.

From 1907 to 1909, U.S. President Teddy Roosevelt’s Great White Fleet is powered by B&W boilers.

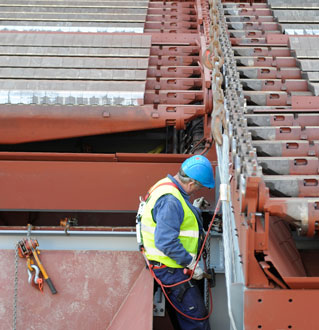

B&W’s pioneering marine boilers triumph during World War I, powering Navy destroyer and emergency fleets. During wartime, B&W boilers were mass produced, following the landmark shop-assembly technique the company began in 1909. B&W boilers powered both maritime vessels and production facilities for all types of war materials. Research continued during this production boom as B&W’s first economizers, a significant aid in boiler efficiency, are manufactured.

Vølund A/S begins making crude oil engines for marine propulsion.

The U.S. Navy contracts with B&W to convert the major ships of the fleet to oil firing.

B&W is a major proponent of and contributor to the American Society of Mechanical Engineers’ (ASME) Boiler Code.

During World War I, B&W produces more than 500 naval boilers and 1,000 merchant units for the emergency fleet of the U.S. Navy and Merchant Marine.

B&W introduces its 350-pound pressure boiler, which operates at a temperature of 660 degrees and is capable of generating electricity for 13,000 homes.

Wilcox’s nephew William D. Hoxie, largely credited for the success of B&W’s marine business, is named president. He is known for revolutionizing marine boiler standards and practices, anticipating and driving the development of high-pressure, high-efficiency stationary oil-firing units, and establishing the company’s first group insurance program “to improve the welfare and security of B&W employees.”

Frank Allen, Max Sherman and Leigh Hoff form the Allen-Sherman-Hoff (A-S-H) company in Pennsylvania to supply premier ash handling equipment and service.

B&W acquires an 84 percent interest in Diamond Power Specialty Corporation, a mechanical boiler cleaning equipment manufacturer in Detroit, Michigan. Diamond had pioneered the development of sootblowers for the efficient cleaning of soot and ash deposits from boiler tubes.

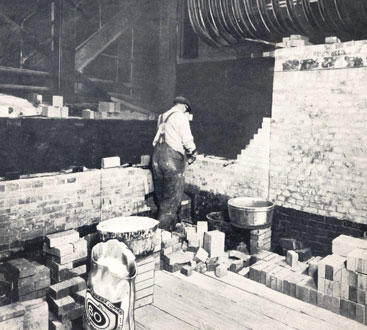

The first engineered refractory brick — B&W 80 Firebrick — is manufactured for the commercial market and proves invaluable in the furnaces of petroleum, chemical, glass and steelmaking industries.

Babcock & Wilcox, Limited and The Babcock & Wilcox Company buy into The Goldie & McCulloch Company Limited of Cambridge, Ontario, forming Babcock-Wilcox & Goldie-McCulloch Ltd. in Canada.

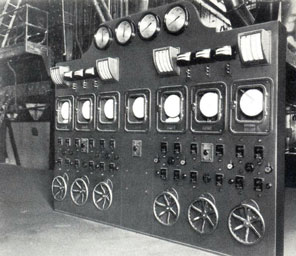

B&W acquires Bailey Meter Company, a Cleveland, Ohio-based boiler control and metering equipment manufacturer. Bailey Meter brings the concept of the water-cooled furnace, mechanisms for measuring boiler performance and combustion control equipment to B&W.

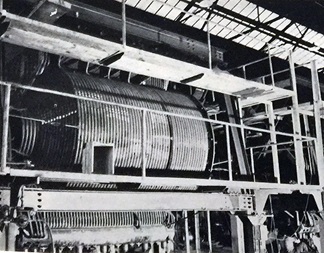

B&W acquires Fuller Lehigh Company, a manufacturer of pulverized coal equipment. The acquisition adds pulverizer design to B&W’s capabilities, which allows increased heat generation per unit of coal in B&W boilers.

The world’s first commercial-size Recovery boiler using the magnesium bisulfite process is installed at the Howard Smith Paper Mills in Windsor Mills, Quebec, Canada.

B&W’s top-of-the-line boiler operates at 1,400 pounds pressure, supplying 275,000 pounds of steam at a temperature of 750 degrees.

Diamond Power markets the first telescopic sootblower, replacing hand lancing as the method for cleaning heat transfer surfaces.

Vølund supplies equipment to Gentofte (1931), Frederiksberg (1934) and Aarhus (1934) in Denmark, the first continuously operating incinerating plants in the world.

B&W’s newly developed fusion welding technique for boiler drums supersedes the riveting method, allowing a more cost effective, sturdy and efficient boiler. B&W pioneers the use of x-rays for the examination of welded boiler drums, eliminating the need to destroy the boiler drum during inspection.

B&W’s Bayonne plant is closed and manufacturing operations and the company’s engineering staff are transferred to Barberton.

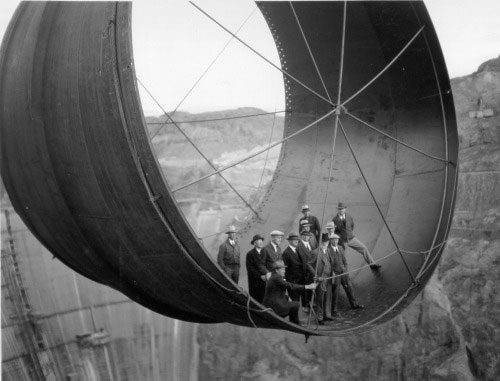

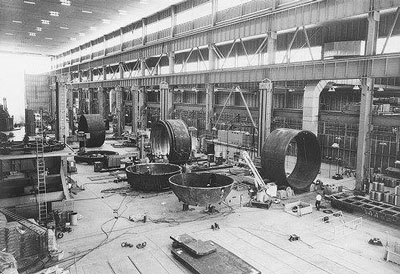

B&W is contracted to build the water pipe, or penstock system, for the Hoover Dam. Due to their immense size, the penstocks could not be shipped by rail, so B&W built a fabricating plant near the dam site which housed some of the largest machines ever in use at the time. Upon the dam’s completion, it was often called the “eighth wonder of the world.”

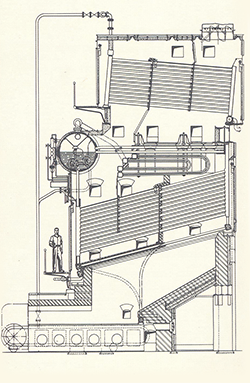

B&W introduces the Integral Furnace boiler – the first boiler to successfully combine a boiler and water-cooled furnace in a completely coordinated unit that could be fired with pulverized coal, oil or gas alone, or in any combination.

Vølund begins to export its waste-to-energy technology outside Denmark.

B&W sells and places into service the first “black liquor” Recovery boiler in the U.S. To this day, black liquor boilers are in use in the pulp and paper industry with equipment specially developed for recovery of chemicals and waste heat in the paper production process.

B&W introduces the Radiant boiler and Open-Pass boiler, both widely used in heavy-duty central station services for high pressures.

During World War II, as during World War I, B&W fabricated marine boilers for steam-powered combat and merchant ships. Pre-war boiler production averaged two to three boilers a week; at the end of the shipbuilding program, B&W produced about 30 boilers a week. In total, 4,100 of the 5,400 major vessels constructed for the war effort were equipped with B&W boilers. Marine boilers dominated the war years, but B&W also forged ahead in research and development.

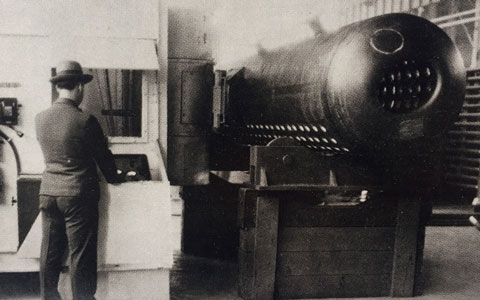

B&W played a major role in the production of synthetic rubber. Other products manufactured by B&W during World War II include the heaviest walled pressure vessel ever constructed for the atomic bomb program, 400,000 rocket motors and cylinders for the Panama Canal’s operating gates.

B&W installs the first commercial Cyclone furnace at Commonwealth Edison Company’s Calumet station in Chicago. The Cyclone design reduces the amount of coal ash leaving the boiler in the flue gas.

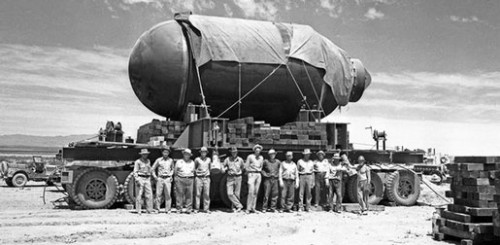

B&W builds a 214-ton containment vessel, known as “Jumbo,” to test atomic detonation for the U.S. government’s Manhattan Project.

Diamond Power introduces a closed-circuit industrial television system to monitor water levels in boiler drums.

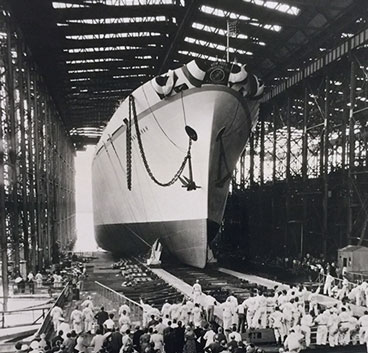

B&W is awarded contracts to design and build boilers for the SS United States, the first American superliner.

B&W introduces the Package boiler, the company’s first integral, self-contained “ready-to-use” boiler unit. The Package, or FM, boiler answered industry’s call for a smaller boiler which could be assembled and erected by a customer onsite with minimal delay.

Plans begin for the world’s largest reheat boiler for Consolidated Edison Company of New York. The single boiler will produce enough electricity for a city the size of Newark, New Jersey.

Completion and opening of plants in Brunswick, Georgia; Wilmington, North Carolina; and Paris, Texas, give B&W a total of 10 fully operational manufacturing facilities in the U.S.

B&W established an Atomic Energy Division in Barberton to consolidate work in the field of nuclear energy.

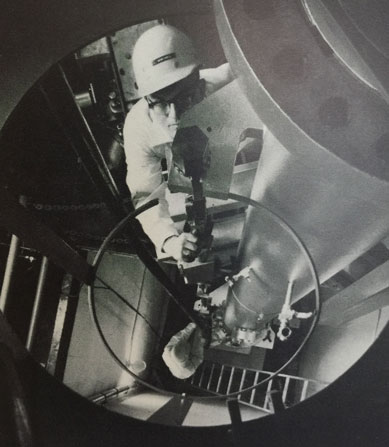

B&W supplies the nuclear power components to the U.S. Navy for the USS Nautilus, the world’s first nuclear-powered submarine.

B&W begins to manufacture and sell the CO (carbon monoxide) boiler for recovering waste heat in the operation of catalyst crackers in the petroleum industry.

B&W’s Atomic Energy Division opens a plant for the fabrication of nuclear fuel elements, cores and other reactor parts in Lynchburg, Virginia. It is the first privately financed nuclear facility built in the U.S.

Philo (Ohio) Power Plant Unit 6 was introduced as the nation's first commercial supercritical steam generator. The unit began commercial generation in 1957 with a nameplate capacity of 120 MW. Its steam generator, designed and built by Babcock & Wilcox, had a maximum pressure of 4,500 psi (31 MPa) and an operating temperature of 1150F (621C).

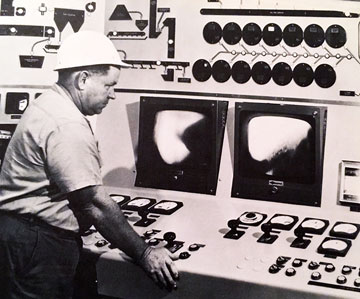

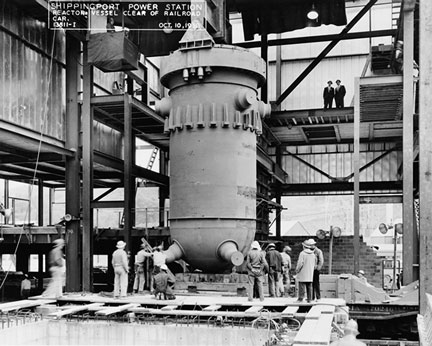

B&W manufactured components for the first full-scale peacetime nuclear power plant in the U.S. in Shippingport, Pennsylvania.

B&W designs and supplies reactors for the world’s first commercial nuclear ship, the NS Savannah.

B&W is awarded a contract to design and manufacture the first shop-assembled carbon monoxide-fired boiler in the world as part of a refinery extension project in Montevideo, Uruguay.

A new B&W 450 MW electric power generating unit — the world’s largest at the time — is placed in commercial operation at the Indiana & Michigan Electric Company’s Breed plant near Terre Haute, Indiana.

B&W designs and furnishes reactor systems for the first privately financed nuclear power station in the U.S., Consolidated Edison’s Indian Point Station in New York.

B&W builds the first experimental, continuous casting unit in the U.S. for Roanoke Electric Steel Corporation.

B&W acquires the Goldie & McCulloch interests in Babcock-Wilcox & Goldie-McCulloch Ltd.

B&W’s Mount Vernon, Indiana, plant opens to produce commercial nuclear vessels.

The Diamond Power Specialty Company obtains its first significant order for nuclear reactor control rod drives from the LOFT (Loss of Fluid Test) reactor in Idaho Falls, Idaho.

The name of Babcock-Wilcox & Goldie-McCulloch is changed to Babcock & Wilcox Canada Ltd.

B&W Canada Ltd. manufactures steam generators for Canada’s largest nuclear power station to date in Pickering, Ontario.

The world’s largest boiler, a B&W-built 1,150 MW supercritical pressure unit, begins commercial operation at the Tennessee Valley Authority.

B&W designs and installs the first-of-its-kind “low odor” Kraft recovery boiler at American Can Company’s Halsey, Oregon, paper mill.

B&W opens a nuclear training facility in Lynchburg, Virginia, one of only two in the U.S. The facility boasts a water reactor simulator used to train the staffs of nuclear power plants.

B&W focuses on research and development, spending more than US $20 million on projects devoted to improving existing products and exploring advanced technologies.

Duke Power Company’s Oconee plant in South Carolina is scheduled for start-up. The start-up is a milestone in B&W’s nuclear program as the station is among the largest investor-owned nuclear power plants in operation.

North America’s first refuse-to-energy plant, built by B&W, begins operation in Hamilton, Ontario, Canada.

Duke Power Company’s B&W-supplied nuclear power station produces a total of 1,783,000 megawatt hours — the most electricity ever produced by a nuclear station in one month — at a capacity factor of approximately 92 percent.

J. Ray McDermott & Co., Inc. (now McDermott International, Inc.), provider of offshore platform construction for oil production, purchases B&W to broaden its energy services.

B&W installs North America’s largest wood-waste burning boiler at Crown Zellerbach’s Elk Falls Mill in British Columbia.

Vølund supplies its first biomass-fired plant in Novopan, Denmark.

A B&W boiler begins operating commercially as the largest U.S. unit burning low-grade coal at San Miguel Electric Co-op’s 448 MW station in Texas.

The first atmospheric fluidized-bed boiler in the U.S., built by B&W, begins operating commercially for the Tennessee Valley Authority.

Manufactured by B&W, the world’s largest dry scrubbing system begins operating commercially at Basin Electric’s Laramie River Station in Wyoming.

Babcock-Ultrapower, a joint venture of B&W and Ultra Systems, marks the first time B&W assumes an equity position in and operates a power plant.

From 1985 to 1990, B&W establishes joint ventures in China (’85), Mexico (’85), Indonesia (’85), India (’89) and Turkey (’90).

One of American Electric Power’s B&W-built 1,300 MW coal-fired supercritical boilers operates continuously for a world record 607 days.

B&W’s first circulating fluidized bed boilers begin operating commercially in Maine and California.

Kal Kan purchases the first selective catalytic reduction (SCR) system sold with a boiler, one of the first projects to meet new California emissions requirements.

B&W designs and builds the world’s largest waste-to-energy facility in Florida. It consumes 2,000 tons of municipal solid waste per day.

B&W completes a nuclear-to-fossil conversion of Consumer Power’s Midland, Michigan, plant, the nation’s largest gas-fired cogeneration facility.

B&W completes and commissions the world’s largest chemical recovery boiler for Howe Sound Pulp & Paper Ltd. in British Columbia, Canada.

B&W completes construction of the U.S.’s first pressurized fluidized-bed combustion system for American Electric Power. The plant receives Power magazine’s “Plant of the Year” award.

Operations begin at B&W’s cogeneration plant in Ebensburg, Pennsylvania, B&W’s first 100 percent built, owned and operated power plant.

B&W erects a Universal Pressure boiler and wet scrubber at Cincinnati Gas and Electric Company’s William H. Zimmer station, the first commercial nuclear plant to be converted to a coal-fired plant and the world’s largest single boiler emissions control system.

American Electric Power awards B&W the largest scrubber installation contract in North America for Ohio Power Company’s Gavin Plant.

B&W’s Clean Environment Development Facility (CEDF) goes on line at the Research and Development Division in Alliance, Ohio, to pursue the advancement of new emissions reduction technologies.

B&W expands its environmental equipment product line with an electrostatic precipitator technology acquisition.

B&W wins a contract to supply Sumitomo Corp. with two 660 MW coal-fired boilers for its Tanjung Jati power plant in one of the first independent power projects awarded in Indonesia.

B&W customers can submit online orders for boiler parts, a feature that makes B&W the first company in the power generation industry to offer formalized web-facilitated commercial transactions.

B&W files voluntary petition for Chapter 11 Reorganization to resolve asbestos liability claims, and emerges from this process in 2006.

B&W International Investments Co., Inc. purchases various business units of the Ansaldo Vølund Group in Denmark to be named Babcock & Wilcox Vølund.

B&W wins a $130 million environmental contract to supply selective catalytic reduction (SCR) systems for a major Canadian utility, the first such units in Canada.

B&W is awarded a contract valued at more than US $100 million to engineer, design, procure and construct Wygen Unit 1, a complete 80 MW coal-fired power plant in Wyoming. The only new-capacity pulverized-coal-fired power plant under contract in the U.S., the project is completed in 2003, ahead of schedule and under budget.

B&W completes a 550 MW boiler replacement in world-record time – less than 22 months – and two large SCRs for a major Northeastern U.S. utility.

B&W Vølund acquires DynaGrate® technology.

Babcock & Wilcox Beijing Company Ltd. books 9,800 MW of new coal-fired boiler orders during the year.

B&W completes spinoff from former parent company McDermott International, Inc.

B&W and Thermax form joint venture to serve the Indian utility boiler market.

B&W Vølund acquires Götaverken Miljö AB of Sweden. (Sold in 2024.)

B&W acquires electrostatic precipitator and emissions monitoring business units formerly owned by GE Energy.

B&W awarded waste-to-energy contracts in West Palm Beach, Florida.

B&W is awarded a contract to provide innovative industrial water-tube boilers with multi-circulation technology for a major steam assisted gravity drainage oil sands project in Alberta, Canada.

B&W supplies the U.S.’s first ultra-supercritical boiler to AEP’s Turk power plant. It is recognized with a Project of the Year Award as one of the most efficient, low-emissions coal-fired power plants in North America.

B&W acquires MEGTEC (B&W MEGTEC), a leading global supplier of environmental control technologies and engineered products. (Sold in 2018.)

B&W completes spinoff of its power generation segment, trades as independent company (NYSE: BW).

B&W acquires SPIG SpA (B&W SPIG), worldwide provider of cooling towers, air-cooled condensers and related services. (Sold in 2024.)

Babcock & Wilcox celebrates 150 years of Transforming Our World.

B&W acquires UniversalAET (B&W Universal), acoustic and emission/filtration system experts serving power and industry customers. (Sold in 2018.)

B&W announces relocation of company headquarters from Charlotte, North Carolina, to Ohio.

B&W is awarded a patent for innovative submerged grind conveyor ash handling technology.

B&W moves its world headquarters to Akron, Ohio.

B&W announces a global partnership for battery solutions with Eos Energy Storage to sell and service the Znyth® zinc battery technology.

B&W introduces the ClimateBright™ decarbonization platform to reduce global greenhouse gas emissions with technologies for carbon capture, hydrogen production and other solutions for the energy transition.

B&W signs an exclusive intellectual property agreement with the U.S. Department of Energy’s National Renewable Energy Laboratory (NREL) for advanced, renewable long duration energy storage technology.

B&W acquires VODA A/S, a leading multi-brand aftermarket parts and service provider for the waste-to-energy and biomass-to-energy markets based in Denmark. (Sold in 2024.)

B&W acquires a majority ownership of a leading solar energy installation contractor, adding to its Renewable segment businesses.

B&W acquires Fossil Power Systems (FPS), a leading designer and manufacturer of hydrogen, natural gas and renewable pulp and paper combustion equipment including ignitors, plant controls and safety systems based in Nova Scotia, Canada.

B&W acquires the assets and businesses of the Optimus Operating Groups, comprising Optimus Engineered Products, Chanute Manufacturing, and Chanute Fin Tube, expanding our HRSG and other heat transfer technology capabilities.

B&W joins the United Nations (UN) Global Compact, a corporate sustainability initiative that provides a global platform for the development, implementation and disclosure of responsible business practices in the areas of human rights, labor, the environment and anti-corruption.

B&W strengthens environmental offerings with Hamon Research-Cottrell emissions control technologies acquisition.

Black Hills Energy selects B&W’s BrightLoop™ hydrogen generation technology for a proposed project to produce clean hydrogen from coal and capture CO2 emissions at BHE’s Neil Simpson Power Plant in Gillette, Wyoming.

B&W announces its selection as the provider of biomass energy processing and flue gas pre-treatment technologies to support the Fidelis New Energy hydrogen production facility and microgrid project in West Virginia.