BrightLoop™ Next Generation Low-Carbon Technology for Power and Industry

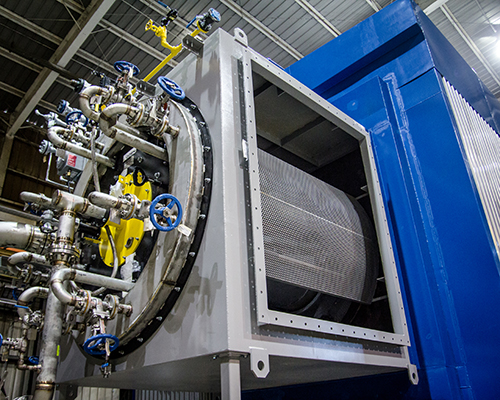

To meet these challenges, B&W has developed an innovative energy production technology that can simultaneously support industry’s low-carbon initiatives and the energy transition. Our BrightLoop™ chemical looping process can be used for a wide range of applications, including hydrogen production.

To meet these challenges, B&W has developed an innovative energy production technology that can simultaneously support industry’s low-carbon initiatives and the energy transition. Our BrightLoop™ chemical looping process can be used for a wide range of applications, including hydrogen production.

The BrightLoop hydrogen production technology can utilize a wide range of feedstocks, including solid fuels such as biomass, coal, petcoke and waste fuels. While the output of the process can be configured in multiple ways, the most beneficial near-term opportunity for using this technology is to produce hydrogen cleanly and efficiently.

The BrightLoop system is highly scalable and can be applied to a range of industrial processes. With its inherent isolation of carbon dioxide (CO2) to enable storage, sequestration or beneficial use, there is no need for post-combustion CO2 scrubbing, thus, significantly reducing both capital and operating costs.

Product output capacity

- Hydrogen

- Steam

- Syngas

- Methanol or other fuels

Advantages

- Solid Fuels can be used as the feedstock

- Low-Carbon Intensity from >95% pure CO2 stream

- Low-Cost Hydrogen production due to efficient process

Applications

- Refineries

- Power generation

- Pulp & paper

- Food manufacturing

- Cement

- Many more

Feedstock

- Natural gas

- Coal

- Petroleum coke

- Biomass

- Biogas

- Organic wastes

To meet these challenges, B&W has developed an innovative energy production technology that can simultaneously support industry’s low-carbon initiatives and the energy transition. Our BrightLoop™ chemical looping process can be used for a wide range of applications, including

To meet these challenges, B&W has developed an innovative energy production technology that can simultaneously support industry’s low-carbon initiatives and the energy transition. Our BrightLoop™ chemical looping process can be used for a wide range of applications, including  Another way that B&W is supporting the hydrogen economy is through our BrightGen™

Another way that B&W is supporting the hydrogen economy is through our BrightGen™