BrightGen™ Hydrogen Combustion

The BrightGen™ hydrogen steam boiler combustion technology from Babcock & Wilcox (B&W) is commercially ready and currently in operation worldwide. In fact, we have supplied more than 60 industrial water-tube boilers firing hydrogen and hydrogen-blended fuels. We have also performed hundreds of gas projects which have reduced the dependency on higher carbon-burning fuels.

The BrightGen™ hydrogen steam boiler combustion technology from Babcock & Wilcox (B&W) is commercially ready and currently in operation worldwide. In fact, we have supplied more than 60 industrial water-tube boilers firing hydrogen and hydrogen-blended fuels. We have also performed hundreds of gas projects which have reduced the dependency on higher carbon-burning fuels.

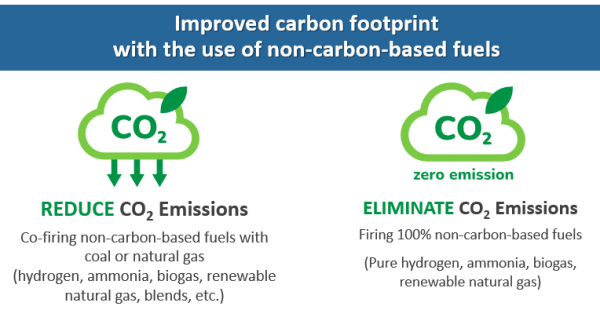

Burning cleaner hydrogen or other non-carbon-based fuels in industrial processes results in lower-carbon intensive byproducts from the combustion process. Hydrogen can comprise 100% of the input fuel or be combined with other readily available fuels. BrightGen technology can be retrofit onto existing equipment or provided with new hydrogen steam boiler installations to fire these fuels efficiently and safely.

BrightGen combustion and boiler technology can be part of a complete decarbonization strategy.

More than 155 years of combustion and steam generation experience is behind B&W’s BrightGen™ hydrogen boiler combustion technology.

Fuel switching considerations

A complete evaluation of the entire boiler system is necessary when considering the potential for fuel switching from a solid, liquid or gaseous fuel and integrating hydrogen or other non-carbon fuels into the combustion process.

B&W’s fuel transition services begin with a thorough boiler performance evaluation consisting of the combustion system, heating surfaces, air system, controls and emissions. More than 155 years of combustion and steam generation experience is behind our BrightGen combustion technology.

- Combustion systems – fuel composition, burners, ignitors, flame scanners, fuel piping/trains, flue gas recirculation

- Heating surfaces – thermal impact including superheaters, reheaters, attemperator capacity, furnace tube metal integrity

- Air system – furnace draft, fans, air heaters, air ducts, overfire air

- Controls – boiler controls, automation systems, burner management system (BMS)

- Emissions – changes in composition, emissions control systems, condensation at stack

B&W can provide a comprehensive evaluation of the overall steam generation system to achieve safe and successful transition to non-carbon-based fuel firing.

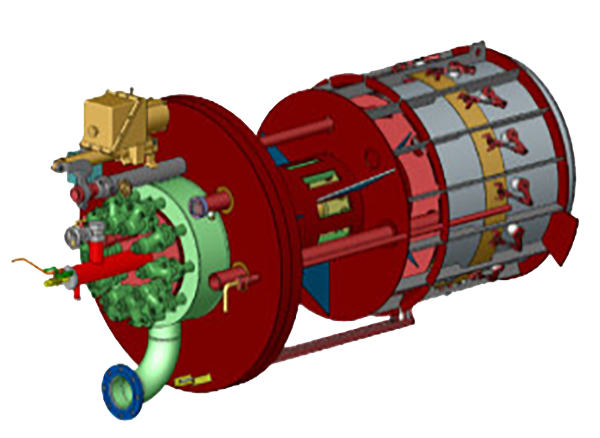

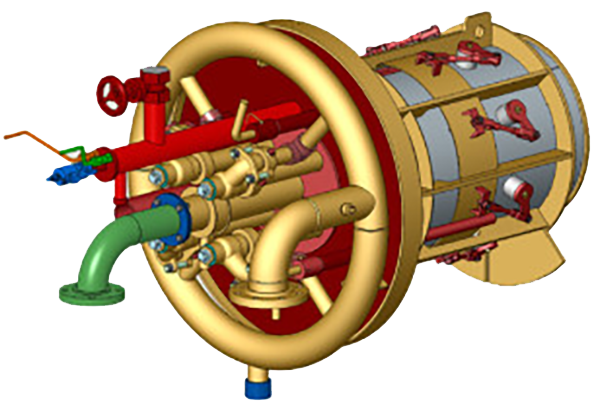

Dedicated Hydrogen Boiler Burner

Dual Fuel H2 and Natural Gas Burner

Products/Equipment

B&W can provide all the necessary equipment needed to achieve a safe and successful transition to non-carbon-based fuel firing, including:

- Industrial hydrogen boilers

- Fuel feed systems/fuel trains

- Burners and overfire air (OFA) systems

- Ignitors, flame scanners and valves

- Heating surfaces (superheaters, reheaters, attemperators)

- Combustion controls

- Burner management systems

Complete gas conversion capabilities

- Design, manufacture and commissioning of natural gas piping and associated equipment, from tie-in point to boiler

- Design, manufacture and commissioning of upgrades to ignitors and flame scanners

- Thermal modeling capability to predict future performance

- Code compliance review and approval (where applicable)

- Executed as supply-only, deliver and erect, or EPC

Read more about our fuel conversion technologies

Industrial hydrogen steam boilers

B&W has supplied more than 5000 water-tube package and industrial boilers with an established reputation for reliability and proven performance in many industries and applications. We’ve used our experience with a wide range of fuels to supply more than 60 hydrogen steam boilers and units which are firing hydrogen-blended fuels.

With the anticipated demand for a wider utilization of cleaner burning hydrogen and other low- or no-carbon fuels, B&W is ready to advance steam generation technology far beyond traditional applications.