Wet ESPs

For utility and power generation applications, B&W’s wet electrostatic precipitators (wet ESP or WESP) are used to control selected emissions, primarily sulfuric acid mist (H2SO4) and fine particulates. For industrial installations, wet ESPs offer highly efficient control of submicron particulate, heavy metals, acid mists and condensed metal fumes and organics.

Features and benefits of B&W’s wet electrostatic precipitators include:

- Low operating and maintenance costs

- Ultra-low particulate (solids, mist and fine particulate) emissions

- Hazardous pollutant reduction

- Optimized system design for sorbent injection technologies

- Total system capability for integration with other pollution control devices

- Well suited for new boiler installations as well as retrofit applications

Dry ESPs

Regardless of the application, B&W’s latest dry electrostatic precipitator design provides many advantages, including:

- High efficiency

- High temperature capacity

- Wide capacity range

- Low maintenance

- Quality mechanical and electrical components for long life

- Advanced controls and software for optimum operation

B&W's experience in industrial emissions control is among the longest and broadest in the industry. Our particulate control experience originated with one of the first commercial applications of industrial ESPs in the United States in 1907.

Electrostatic Precipitator (ESP) Rebuilds & Upgrades

Improvements for decreased emissions and improved efficiency

Aging technology and lack of support from some original equipment manufacturers has resulted in lost productivity and reduced efficiency for many electrostatic precipitator systems. ESP products and services provided by B&W are designed with one goal in mind— to help keep your electrostatic precipitator functioning at peak performance. Our vast industry experience enables us to provide integrated solutions to enhance equipment performance, regardless of original manufacturer. B&W’s ESP aftermarket parts, service and upgrade business, formerly known under the Preciptech brand name, provides engineered upgrades, quality components and services to help keep your electrostatic precipitator running efficiently and effectively.

Our combination of innovative products and services include:

- Collector plates

- Rapper components and parts

- Discharge electrodes

- Insulators

- Single- and 3-phase power supplies and controls

- Access doors and door seals

- Electrical performance enhancement hardware and software

- Upgrades, rebuilds and conversions

- 24/7 remote diagnostics

- Field services and operating and maintenance training seminars

- B&W can upgrade virtually any existing ESP, regardless of manufacturer.

ESPs for Diverse Applications

B&W Environmental has extensive experience with both dry and wet technologies, and have installations in a wide range of applications, including power generation, waste-to-energy, cement, chemical, oil & gas, pulp & paper, metals/steel, and others.

In this video, our Electrostatic Precipitator Expert returns to talk about powerful precipitators for wood-fired applications. He discusses the most significant improvements he has seen in his career and one diagnostic check he recommends on an operating ESP.

Pulse Jet Fabric Filters

B&W has supplied some of the largest and most efficient pulse jet fabric filters in the world. Our design innovations offer features not available from other suppliers, such as our long bag (10 meter) technology, enhanced pulse system, and online maintenance capability. Our fabric filters, or baghouses, offer high particulate removal efficiencies, reduced maintenance costs, and reduced operating costs. Integrating fabric filters with our sorbent injection and flue gas desulfurization (FGD) technologies also provides high removal efficiencies of hazardous air pollutants in a variety of applications. It can also be used with an electrostatic precipitator (ESP) for greater mercury (Hg) control. Our innovative fabric filter technology can be found in a variety of industries including steel, cement, incineration and steam generating boilers that utilize a variety of fossil- and biomass-based fuels.

Wet Gas Scrubbers for Refinery FCCs

Refiners can take advantage of B&W’s more than 155 years of experience and global leadership position in providing energy and air pollution control equipment to a wide range of industries. As a licensee of the ExxonMobil wet gas scrubbing (WGS) technology we can help refiners to reliably meet stringent fluid catalytic cracking (FCC) emissions regulations with well-proven technology. Developed by ExxonMobil in the 1970s and now licensed by B&W, the WGS technology removes particulates and sulfur dioxide (SO2) by intimate mixing of the flue gases with an aqueous scrubbing liquid. The technology can also be enhanced to meet tighter restrictions on nitrogen oxides (NOx) or particulate.

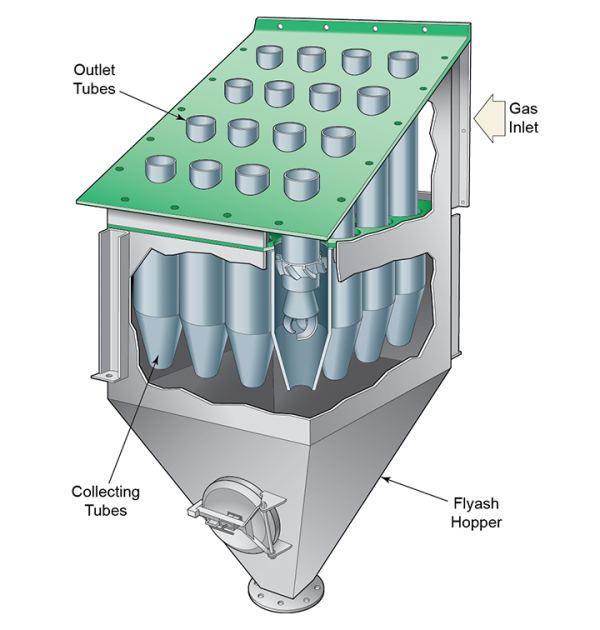

Aftermarket Parts/Service: Multiclone® Dust Collectors / Turbulaire® Scrubbers

B&W continues to support existing installations of the Multiclone® dust collector system and the Turbulaire® scrubber from the former Joy/Western Precipitation product line. We can provide service, component rebuilds and replacement parts. Both of these technologies serve a range of unique applications and industries.

BREF Solutions

The European BREF regulations will require all large combustion power plants to comply with stricter air emissions limits by 2022. This includes limits on mercury (Hg), sulfur dioxide (SO2), nitrogen oxides (NOx), and particulate matter (PM).

Babcock & Wilcox (B&W) has the proven technical experience, know-how and responsiveness to help you lower air emissions to acceptable levels. Our air emissions regulations experience along with extensive boiler design and combustion knowledge makes us uniquely qualified to consider how each environmental solution will affect performance and operation of existing power plant equipment.